- Follow Fifteen Flatout on WordPress.com

Albion Yard

Albion Yard- Wordless Wednesday, Getting to the Point..

- Feel Good Friday, A Step Away..

- Feel Good Friday Improving Bachmann’s Standard Class 5

- Wordless Wednesday Heljan Class 47

- Noughties Bachmann Makeover Part 2

- 2024, Motivation Monday, First One In, Fifteen Minute Heros

- Last One Out 2023, with Francis Bourgeois

- Merry Christmas 23

- A noughties Bachmann Makeover

- Warley 2023 images from the trade #7 (wordless Wednesday)

The Caffinated Engine Driver

The Caffinated Engine Driver Chris Nevard

Chris Nevard- The British Rail Ham Sandwich

- St George’s Day 🏴

- Pipe Organs & Spiders’ Web Sites.

- The Thong & Flasher

- Clever Cat Spots Business Opportunity

- Monochrome Madness: Waving Wonders and Exploding Moonshine on Flat Holm

- Whimsical Wonders at Brew Street: Basil's Brush, Waving Willy, and the Mystery of the Rooftop Duo

- On This Day in History

- Mysterious Fires, Corpses & The Cayman Islands

- Streamlined SDJR 7F

Colin Peak

Colin Peak The Farthing Layouts

The Farthing Layouts- Slater's GWR dia E37 Tri-compo clerestory coach

- Dirty fingers: Trial and error with bricks and mortar

- God Rest Ye Merry Gentlemen

- The station building: Walls and gables

- Copenhagen to Penzance by rail

- A Pannier of mixed parentage - GWR 1854 PT (2)

- The Great Unrest - Modelling the 1911 railway strike

- Edwardian mischief - Modelu & Andrew Stadden figures

- Slater's GWR dia. C10 clerestory coach

- Fifth bite: The Station

Michael’s Model Railways

Michael’s Model Railways Model Railways of Oly Turner & Chris Matthews

Model Railways of Oly Turner & Chris Matthews Off The Beaten Track

Off The Beaten Track Paul’s Fantatsic Workbench

Paul’s Fantatsic Workbench- Drystone Moss: a 006 pizza - track painting

- A first 006 diesel - bonnet

- A first 006 diesel - cab

- A first 006 diesel - footplate and chassis.

- Unimat 3 self-centring 4-jaw chuck

- Dogleg Jenny and the Staedtler Compasses

- A Busch 'Bauwagon' in 006

- Drystone Moss: a 006 pizza - track and electrics.

- Copperclad sleeper gapping jig.

- Drystone Moss: a 006 pizza - baseboard

Paxton Road

Paxton Road- For Sale: New Brunswick Southern GP38-3...

- Friday Update: Twenty-six Four Twenty-four…

- A dirty Sweep...

- Lochdubh lament…

- Back to the drawing board: A new 009 kit...

- Commission: Dirty Southern tank engines…

- Hilton and Mears Leasing…

- Scottish Speedlink: Cameron Bridge…

- Friday Update: Nineteen Four Twenty-four…

- Commission: Seeing double - a pair of Pecketts in 009…

Phil’s Workbench

Phil’s Workbench- Saturday Film Club: A tour of Killybegs model railway

- Off to the NGRS

- Selly Oak lives!

- Wanted: Hornby Church R599

- Tri-ang shop in "The Collector"

- (Cake)boxing clever

- Statfold Barn 2024

- Saturday Film Club: Let's look at a Black Five

- Not painting

- Water, signal levers, wagon loads and a photo plank in the May issue of BRM magazine

West Halton Sidings

West Halton Sidings Woodend & Beyond

Woodend & Beyond

Wordless Wednesday 25th October 2023

Posted in bird watching, Photographs, wordless Wednesday

Tagged cygnet, swan, water, wednesday, wings, wordless

Leave a comment

Wordless Wednesday 11th October 2023

Posted in Cyfronydd, Heritage, locomotives, Photographs, railroad, railway, Welshpool & Llanfair Light Railway, wordless Wednesday

Tagged Cyfronydd, Drefaldwyn, Light, Llanfair, railroad, railway, Welshpool

Leave a comment

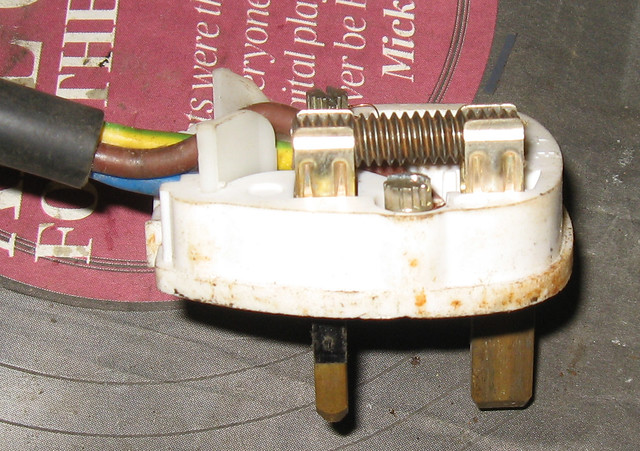

Wordless Wednesday 19th July 2023

Posted in electrical, Photographs, safety

Tagged 13A, danger, dangerous, fuse, hazard, plug, studding, wire

2 Comments

Wordless Wednesday 22nd March 2023

Posted in bird watching, canals, wordless Wednesday

Tagged canal, grand, heron, mooring, no, private, union, water, wednesday, wordless

Leave a comment

Wordless Wednesday 8th March 2023

Posted in Heritage, locomotives, Photographs, railroad, railway, wordless Wednesday

Tagged blue, engine, loco, locomotive, Ropely, steam, tank, Thomas, wednesday, wordless

Leave a comment

Battling The Brambles

The Welshpool & Llanfair Light Railway is just eight miles long. Put another way that means there are sixteen miles of lineside verge with their associated fences, hedges and ditches that need to be maintained. Vegetation within three metres on the track centre line can be kept trimmed using a tractor mounted flail carried on a railway wagon.

Much of the out of reach stuff can be left to grow wild and it provides a lovely habitat for wildlife. Where the line is on an embankment it is periodically necessary to clear the vegetation back so that the Civil Engineers can inspect the structure. One such structure is the embankment on the upper part of Castle Bank where at its highest the track is about 6m (20ft) above the surrounding land.

A decade or so ago this embankment was undermined by a rabbit warren and a significant amount of earth moving was required to stabilise the ground.

Embankment looking towards Coppice Lane and Welshpool

Embankment Looking Towards Castle Caereinion Station

The Fence2Fence team have arrived on site. The tools have been carried up on small trolley that can be dismantled to be transported in the back of a small estate car. There was an Engineering Possession in force and no other rail movements were authorised for the weekend.

The sides of the embankment were covered mainly in brambles and nettles interspersed with hazel, elder, ash, and blackthorn. The brambles were hacked down and the various tree species coppiced – they will soon grow back.

A relatively new volunteer gets stuck in.

There was nothing cut down that was large enough to stack for later recovery as locomotive lighting up wood plus some of the ash saplings were showing signs of the ash-dieback disease. Burning on site was chosen as the best way to clear the debris.

On gentle slopes the petrol engined strimmers were effective at clearing the undergrowth.

On the south side of the railway there is an Organic Waste Remediation Plant that is owned and operated by Hafren Dyfadwy. This discharges treated water into a ditch that then passes through a pair of glazed earthenware pipes under the railway thence onwards to the River Banwy.

The adjacent plant’s discharge point.

The headend of the culvert back in March 2018. Note the position of the fallen tree.

The fallen tree was slowly sinking into the water course and was now posing a significant threat of blocking the entrance to culvert beneath the railway track.

With the surrounding vegetation cleared, a length of rope and several people working together the very rotten section of tree was hauled out of the way.

The semi-collapsed tree in this picture will have to be removed before it crushes the fence and or falls into the culvert seen the pictures above. As there will have to be negotiations with the neighbouring farmer the felling will most likely take place in the autumn.

The last task on site was to rake the ballast shoulders back into place where they had been trodden down.

Just outside Castle Caereinion Station there is an active badger sett and they have recently excavated a new entrance adjacent the the railway and deposited the spoil on the ballast.

End

Wordless Wednesday 1st March 2023

Posted in Heritage, locomotives, Photographs, railroad, railway, Welshpool & Llanfair Light Railway, wordless Wednesday

Tagged Alishan, forest, Llanfair, railway, Taiwan, W&LLR, Wales, Welshpool

Leave a comment

Derailment

These pictures were taken getting on for half a century ago and they feature a little steam engine that has come off the rails.

The engine is Pixie, a Wren class saddle tank locomotive, that was built by Kerr Stuart & Company at their works in Stoke-on-Trent in 1922, works number 4260. After a busy life in a quarry Pixie was retired and for a while sat in the garden of the Leather Bottle public house in Harpenden.

It subsequently moved to the Iron Horse Rail Road (IHRR) in Leighton Buzzard who had leased the, by then, unused section of the old Leighton Buzzard Light Railway. The IHRR soon morphed into the Leighton Buzzard Narrow Gauge Railway. Back then track was not in very good condition and so occasionally a wheel or two would part company with the rails.

The incident documented here happened at the location shown on the two maps below.

https://maps.nls.uk/view/114483291

Pixie has derailed on, what was then, the steep slope down from Bryans Loop. From the pictures it would appear that before rerailing commenced the carriages were removed from the train. Whether they were just pulled back to the loop or right back to the station at Stonehenge Works I can’t recall.

According to the LBNGR Archivist, who has checked the Guards’ Journals, the most likely date for this incident is 18th July 1976.

Thankfully the only damage was to the driver’s pride. Re-railing would have been done with either jacks or more likely with a length of old rail and some sleepers as a fulcrum to lever the loco up and back onto the track.

End

Posted in Heritage, LBNGR, Leighton Buzzard, locomotives, Pixie, railroad, railway, track, train

Tagged derailment, train, wreck

Leave a comment

Wordless Wednesday 22nd February 2023

Posted in Heritage, Photographs, railway, wordless Wednesday

Tagged 29, Grosmont, J27, Lambton, loco, locomotive, NYMR, P3, steam

1 Comment